Welding inspections | QAQC

Our mission is to ensure that manufactured steel products meet the established quality standards, codes, and norms. We take care of welding quality assurance, process selection and welding work supervision. Our task is to prevent possible manufacturing defects, reduce waste and contribute Client to overall success.

Who we are

We are a small team of welding coordinators located in Estonia, Tallinn. We play a role in overseeing welding operations and ensuring they are carried out as per Client’s needs and requirements.

As a welding coordinators or site inspectors, we act as the “eyes and ears” of the Client, representing their interests and ensuring that welding operations are carried out in accordance with the required codes and standards.

Our inspectors obtain several certification degrees such as IWE, VT-2, PT-2, pressure vessel certification and several others.

As welding inspectors, we can handle a combination of desk and site responsibilities. By effectively managing both desk and site work, we can ensure that the product is assembled and manufactured as per Client specs and drawings.

Acting as the Client’s representative we check but not limited to the following:

That WPS/PQR are followed

Verification of welder qualification

What we do

Inspection of pipe spools with endoscope

Inspecting pipe spools with an endoscope is a common practice for ensuring the integrity and quality of piping systems, particularly when they are difficult to access.

This method is particularly useful for industries such as oil & gas, chemical manufacturing, and water treatment, where the integrity of piping is critical to safety and operational efficiency.

The images or video footage can be recorded for documentation, analysis, and reporting purposes.

Welding inspections (ad-hoc, second or third party)

Where needed, we are ready to act as 2nd and 3rd party inspectors. Second-party inspectors provide internal oversight and quality control, while third-party inspectors provide an independent and impartial assessment of the welding work.

Depending on the specific project or requirements, either or both types of inspectors may be involved to ensure that the welding work meets the necessary standards for safety, performance, and quality.

Site management

Our guys are physically fit to perform QC checks on site. Using proper EHS equipment we can perform welding inspections at height and confined areas.

NDT

Getting NDT results (protocols, photos, X-ray films) faster can be achieved through effective planning, communication, and proactive management. We do that job for the Client.

Prior to NDT application we are checking the weld log, composing a weld map with all the required data for proper NDT inspection.

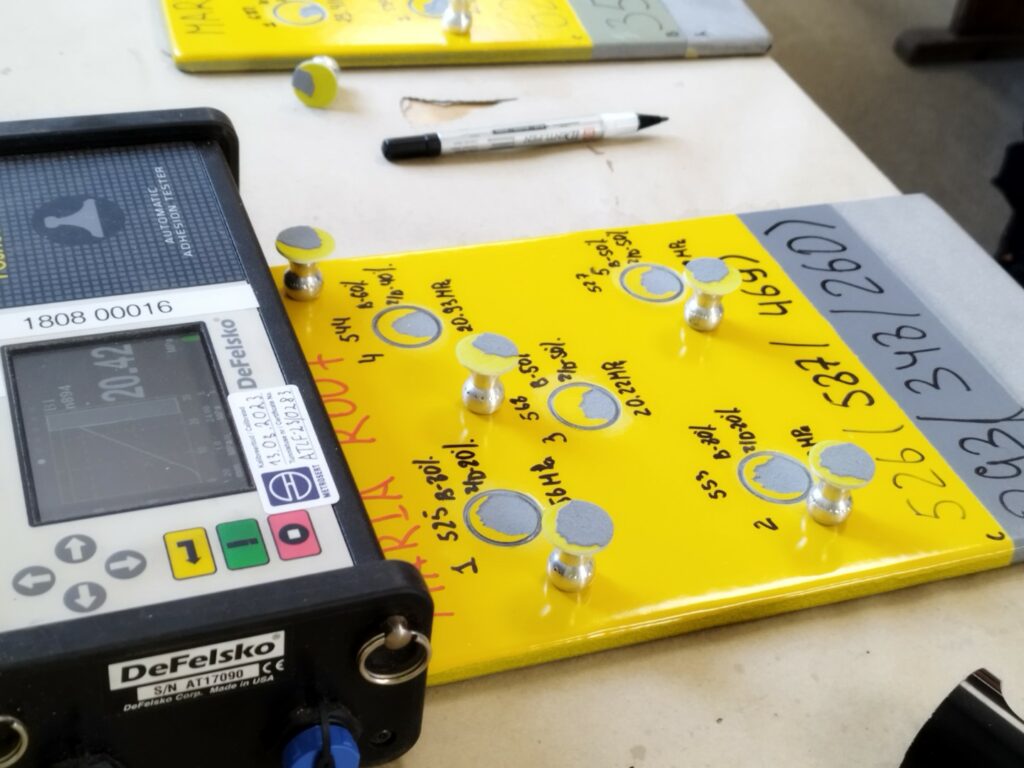

Surface treatment inspection

- Surface roughness evaluation

- Blasting quality

- Pull off testing

- Dust testing

- MEK testing

- NDFT measurements

Hydrostatic testing of piping and pressure equipment

We check all gasket surfaces of flanges on the matter of mechanical damages, perform visual check of inner surface of the vessel, ensure that bolts are torqued as per spec.

Let us take care about your inspection of hydrotesting activities.

Key references

Below are the most challenging projects we’ve been participating in

Year: March 2024 – January 2025

Activity: 2nd party shop inspection of pipe prefabs for LBC renaissance project

Client: LBC Tank terminals

Manufacturer: Verwater Estonia OÜ, www.verwater.com

Activity: Ad-hoc shop inspection of storage tanks manufacturing

Client: GriJana inspection company / Aker Carbon Capture

Manufacturer: Estanc AS, www.estanc.ee

Year: August 2023 – December 2023

Activity: 3rd party shop inspection of heat exchangers

Client: DOW

Manufacturer: Nordic Custom OÜ, www.nordic-custom.com

Year: October 2022 – July 2023

Activity: 2nd party shop inspection of assembly and welding of integrated template structure (ITS)

Client: Wintershall DEA Norway

Manufacturer: Marketex Offshore Constructions, www.moc.ee

Activity: Full time welding coordination & NDT management of LNG FSRU subsea pipeline welding as per DNV-ST-F101

Client/Erection company: MT Grupp UAB, www.mtgroup.lt

Activity: 2nd party shop inspection of gas flow modifiers

Client: North Caspean Operation Company (NCOC)

Manufacturer: AVP Integral OÜ, www.avpintegral.com

Activity: 2nd party shop inspection of LNG pump columns for Arctic LNG2 project

Client: Saipem S.A.

Manufacturer: PTG Group Oy, www.powertechgroup.fi

Year: October 2020 – May 2021

Activity: 2nd party shop inspection of production of rectification columns for Leuna project

Client: UPM biochemicals GmbH

Manufacturer: Estanc AS, www.estanc.ee

Contact

Please send your inquiry here:

info@limika.eu

Company legal information

OÜ Limika

Reg. code: 14886160

Address: Uus-Volta tn 9/1-205, Põhja-Tallinna linnaosa, Tallinn, Harju maakond, 10416